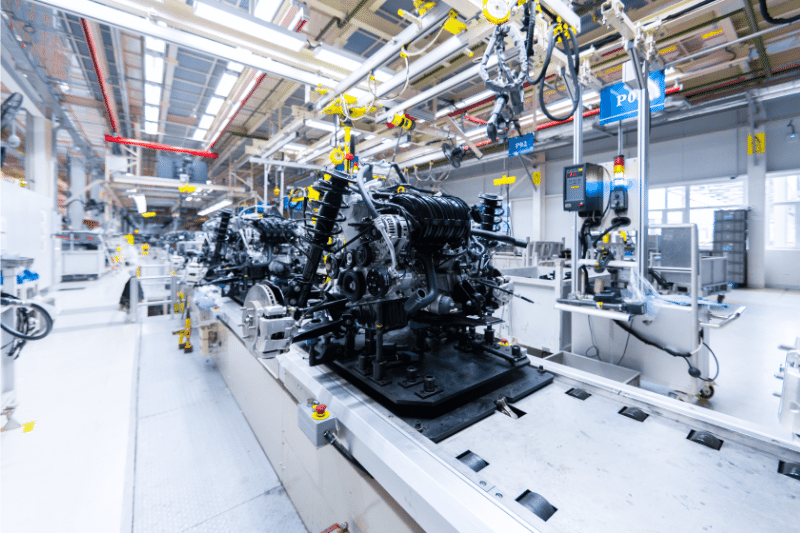

Assembly manufacturing transformed the way goods were brought to mass-market, ranging from cars to consumer electronics, and ERP systems tie in perfectly to the way everything from light manufacturing to industrial assembly lines operate.

Like assembly line manufacturing, ERP systems improve efficiency and optimise processes, increasing automation to free up personnel and streamlining manual actions to further reduce labour costs and time spent on repetitive tasks.

Why ERP systems matter in manufacturing

Manufacturing is a complex industry. Unlike the services sector, where productivity often depends primarily on clerical and administrative processes, manufacturing also has inherent dependencies on a physical supply chain, including the availability and cost of materials.

Running an efficient organisation means matching the administrative and material elements of the business and optimising across the board. This can be achieved using IT systems but should not come at the cost of deploying unnecessary additional resources.

By using ERP systems to optimise assembly, you can accurately project the total cost of manufacture for a given product, allowing you to set the correct price when you take it to market, both to maximise profits in the short term, and to adjust pricing to any changes in the supply chain in the future.

How ERP systems can help manufacturers post-COVID

The COVID-19 pandemic brought significant economic disruption to many industries, and in some cases shut down manufacturers’ assembly lines completely for several months.

As we move beyond the Coronavirus pandemic, manufacturing ERP systems like SAP Business One can help firms to manage pressures both externally and from within, including manufacturing processes and supply chain concerns.

SAP B1 works across your entire organisation, from materials planning, to stock and inventory, to administrative departments and back-office processes, giving you a single central platform to optimise efficiency across your whole operation.

Enable adaptation to drive future growth

Since the start of the millennium, businesses across all sectors have faced a variety of significant disruptions and upheavals.

Just some examples include:

- Terrorist attacks including 9/11 (2001) and the London 7/7 bombings (2005)

- The deep global recession triggered by the ‘credit crunch’ of 2007-08

- Natural disasters like the 2010 eruption of Eyjafjallajökull

- The global economic shutdown triggered by Coronavirus and COVID-19

In each of these incidents, the manufacturing businesses that were able to thrive were those that adapted most quickly to the emerging circumstances.

During the first lockdown, for example, some businesses pivoted overnight to activities deemed ‘essential’ in order to avoid closing down completely.

In extreme circumstances, you must adapt to survive. ERP systems give you the business-wide overview and insight you need to not only achieve this, but to do so with the best possible results.

To find out more about how SAP Business One ERP systems can help your assembly and light manufacturing business to cope with whatever the coming years bring, get in touch today and book your free consultation with APH.